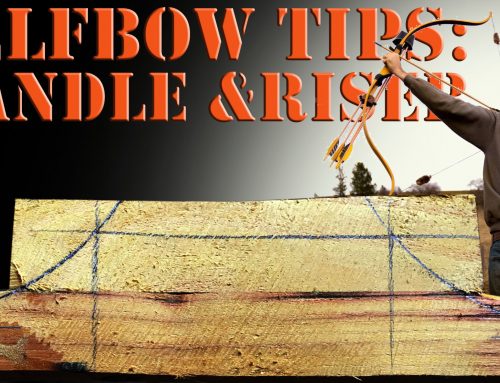

The bow building tools you select to build a selfbow or other primitive bow will depend on your own preference and the type of wood you’re working with. For instance, when working with Eastern redcedar or whitewood boards, I’ll use a small block plane extensively for shaping and tillering but I never use one when working on Osage. The soft, straight grained cedar reacts to a block plane very well, but the hard knotty Osage does much better with a scraper.

My tool selection is very simple. You’ll need a tape measure for laying the bow out. A compass and fine tip sharpie is useful for scribing the lines for limb thickness. For Osage and any of the white woods, about 90% of the work will be done with a draw knife with an 8 to 10” blade. I’ll use that for everything from removing the bark and sapwood, and getting the stave to one ring (for Osage) on the back, to shaping and tillering the limbs. I’ll even turn the drawknife up on edge and use it as a scraper. After that, a hoof/farrier’s rasp comes in handy for shaping up limb tips, handles, fades, and site windows (if you’re going to cut one in). A hoof rasp doesn’t follow the grain at all like a semi-sharp (more on this in a moment) draw knife will. So, if you’re using it for tillering, you’ll need to keep close watch that you’re following the grain. For Osage I do most of the tillering (which we’ll describe in the section by that name) with a drawknife turned on edge and using it as a scraper. For whitewoods like hickory, I’ll rely much more on the hoof rasp. Most whitewoods will be pretty clean, meaning that there won’t be a lot of knots and dips in the wood grain so there’s no real need to use a tool that follows those knots and dips. The coarse side of a hoof rasp takes a lot of wood off quickly so use with caution.

Additionally, a pocket or sheath knife is useful for working around knots in the back of a bow and, of course, you’ll need sand paper for smoothing everything out. Like I mentioned to start, redcedar and very clean whitewoods can be worked with a small block plane. For cutting the nocks in I use a 1/8 inch chainsaw file. Also, a bow square will come in very handy when it comes time to place the arrow shelf and as a tool to measure final tiller. All together you should be able to round up the necessary tools for around a hundred bucks if you don’t mind searching eBay and antique shops.

One additional tool that will come in very handy, especially if you’re working with Osage or other wood that’s often crooked, is a heat gun. I picked mine up for less than $50. This will be very useful for making quick adjustments in limb tip alignment, bending reflex into the tips, etc. Last, you’ll need some sort of tillering rack to hold the bow as it’s drawn so that you can see how the limbs are bending.

The description above is an excerpt from my bow building book, The Traditional Bowyer’s Handbook

Great Site! I love your videos. I have recently gotten into bow building and made a red oak board bow that works alright. I would love to make a bow from a stave though, but because I live in Alaska the only hardwood I have available to me is Birch, which I heard can make a good bow. What do you do differently with a white wood like this than an Osage stave?

Hi Branson,for most whitewoods you’d make the bow a little wider and, perpapse, a little longer to distribute the stress over a larger area. The design in my book, made a little wider, will work well for most whitewoods. ch