This video will wrap up the board bow series where we make a primitive long bow from a maple board we picked up at Home Depot. At the end of part 3 we shot the bow through the chronograph and were shooting around 136-138 fps which is ok, but certainly not great. In this video we talk about how bow design influences the speed and efficiency of a bow. We also talk about the trade offs between a very safe design, like the board bow we built, and more high performance designs.

To get started I show an easy method for measuring the draw weight of the bow using a common bathroom scale. Then we shorten the bow a little to raise the weight and reduce limb mass which will have the added benefit of increasing the efficiency of the bow. After shooting the bow through the chrono for a second time, I reduce mass in the limb tips to reduce inertia even more and we squeeze a little more speed out of the bow.

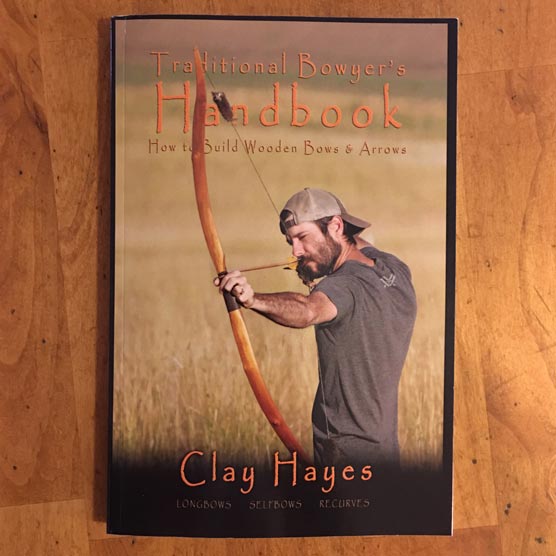

To wrap thing up, I shoot my 50# osage recurve, the bow I hunt with, through the chrono just as a comparison. Even though my hunting bow is drawing only 50 lbs at 29 inches, it shoots the same arrow much faster than the straight limbed maple bow. This doesn’t have so much to do with the materials the bows are made from, but has everything to do with the design of the bow. This video is a great primer for thinking about bow design and how that influences performance. If you’re interested in getting the most out of the bows you make, check out the Traditional Bowyer’s Handbook. I discuss all these things in much greater detail in the book. There’s even a chapter on how to make a two piece takedown!

Great job

Good info

Thanks again Clay for sharing your knowledge it’s much appreciated.

I bought your book through amazon and read it over Christmas. A lot of great information there.

I was encouraged to build another Yew bow I glued together a couple billets and carefully built what I thought to be the best bow I had made to date.

At the tillering stage i heated a limb to take out some propeller that was in the limb.

Latter on in the day I strung the bow and it exploded right where it had been heated. This is the second time this has happened to me. The limb didn’t crack. It literally shattered into fragments.

There is a little confusion here in regards to bending wood in your videos on bow building you endorse steaming as the safe method. I think for me that I will follow this approach.

In your book you use dry heat.

Any thoughts on this matter would be appreciated.

Thanks again for taking the time to write a great book on bow making.

Sincerely,

James Belch

Steam is definitely the safer option but you have to wait for the introduced moisture to dissipate. Yew tends to be a brash wood to start with so, when using dry heat, it is easy to drive the moisture content down making it even more brash. Brash meaning volatile. For yew, I’d use the method that Weylin described in the book, steam or boil, then finish off with dry heat to set the bend. Also, when using dry heat, avoid the bow’s back as much as possible. apply most of the heat to the belly side.

One thing to warn the board bow builder about is that many hardwood suppliers do not distinguish between hard (rock or sugar) maple and soft (swamp or red) maple wood. Neither do they distinguish between hickory and pecan, the latter of which they often sell as hickory. While pecan may make an adequate bow, it is not nearly as good as hickory. I have sorted through the same batch shipment of maple 1x3s at a hardwood store and found both hard and soft maple in them. Buyer beware. You have to really know your woods.

Another great video I highly recommend both books for anyone who is interested in traditional bow hunting or bow building. There is so much knowledge being shared in the Traditional Bowyers Handbook for a new bowyer to learn from. I myself have learned a great deal and still have chapters left to read! Keep up the good work and I look forward to seeing/learning more!

Thanks Ryan, I’m glad so many people are leaning new tips and tricks from the book. ch

Good point Ivan! I’ve never come across soft maple in a hardware store so don’t really know how common it is to find. You’re spot on about the difference though. I made a bow from red maple once. Although it held together, the wood was so spongy that it took about 6 inches of set. It barely straitened out at all when unstrung!

Thanks Clay for a very informative series. I appreciate how you thoroughly explain the process and the dynamics that are in any bow. It was done not taking for granted that your students should know “such and such”.

I have tried boards bows with limited success but once I combined bamboo with its partner hardwood the bow became indestructible. Bamboo is amazing!

I trust you are enjoying the “off” season. Today is -30*C. A good reason to enjoy a book by the fire.

Traditional regards,

David Sherwin

Ah yes, the off season. I was out just the other day shooting footage for a new series on tracking and trailing. Beyond the blood trail! Should be good. ch

I enjoyed the 4 part series at 62 and retired still learning new things.

I lost my good eye at 28 yr, so never did get a chance to get into bow hunting.

I didn’t want to not be able to track an animal and not recover it.

I still have a 25 lbs Shakespear Fiberglas now I got for Christmas at ten.

Back in th day I did alright I shot a killdeer bird in flight at about 30 yards, my dad was watching and couldn’t believe what he say. Maybe I’ll try and build a bow for my grandson and granddaughter.

Stay tunned

Thanks and it’s great what you’re doing.

Keith Daniel (one eye doc)