Eastern red cedar is in the juniper family and it is very common throughout the east and Midwest. As you move into the western states it’s replaced by other closely related species, common juniper, rocky mountain juniper, and a few other species. They will all make great primitive survival bows if they are backed with some other material like rawhide or sinew. The availability of ERC, the fact that it works easily with hand tools, and dries very quickly make it a great choice for a quickly made wood survival bow.

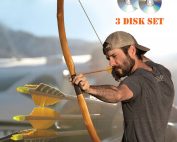

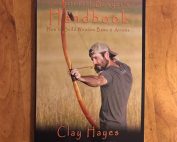

After forging a tomahawk and bow building knife (you can check out these videos on the YouTube channel), Clay uses the primitive tools to build a sinew backed eastern red cedar survival bow from a freshly cut tree. This video covers the entire primitive bow building process. Clay begins by roughing out the longbow from green bow stave before drying it, backing the bow with sinew, and tillering after the sinew dries. Typically you would dry the bow stave before roughing out the bow but this is not necessary with ERC. The initial moisture content in these trees is already low (usually in the mid 20% range) and drops rapidly in low humidity environments. This stave reached 10% after just a few days in a drying box.

Sinew backing will protect the bow’s back and add a lot to the performance of the bow as well. As the sinew dries it shrinks longitudinally and will often draw the bow into a reflex or backset. This pre-loads the limbs at brace and results in a more efficient and often times faster primitive survival bow.

This video is the third in a series following Clay through the primitive bow making process. Starting with using a coal forge to build a tomahawk and knife from old rasps, then using those tools to build the primitive bow and arrow.

The next video in this series will cover making primitive arrows from river cane and hand forging trade point arrow heads (primitive broadheads). When the primitive hunting gear is complete, Clay will bow hunt wild hogs with it. If you’re looking for a comprehensive guide to building wood bows, including sinew backing, two piece takedowns, whitewood bows and more, visit www.patreon.com/clayhayes and check it out.

Great video, good job on that bow. I was impressed with how well your knife worked! Steve

Have you read the gear list of the ice man at iceman.it ?

He lived about 5300 years ago in the cooper age and was frozen until found in 1991 when found by hikers. He had an unfinished stave with him, a string, arrows with flechings, broad heads. axe with a copper head, deer skin quiver, etc. They have photos of the gear online.

Hi

In this video clay used a fresh cut tree to make the bow. Here you have mention the moisture and humidity which have been used. Actually I want to know Is there any absolute guideline for moisture and humidity which I have to follow to make such kind of bow?

Idealy you want the moisture content in the wood to be somewhere between 5-10%.

Great post.

Clay,

Are you ,as a rough guideline, suggesting that a finished selfbow should hold ca 5-10% moisture at which time it would be suitable to seal it up?? This is one very important step. I think my first hickory selfbow may have had “too” much moisture content and as a result I may have lost a bunch of performance. Could you elaborate on this? Also the same for sinew backing; how do you know when it’s cured out?

Thanks Neal

Hickory is bad about sucking up humidity and holding a high MC. The best thing for hickory is to put it in a hot box for a while and drive the MC down to around 5 or 6%, then seal it up. On my osage bows I shoot for something in that range as well.